International researchers have developed an advanced artificial intelligence (AI) algorithm capable of detecting and classifying defects in green coffee beans with unprecedented accuracy. This significant achievement for the global coffee industry was revealed in a study titled “Comparative Analysis of YOLO Models for Green Coffee Bean Detection and Defect Classification”, published in Scientific Reports, Volume 14, 2024.

The research team, from Sylhet Agricultural University in Bangladesh and Gifu University in Japan, led this project, focusing on applying YOLO (You Only Look Once) models to detect defects. The study aims to enhance coffee production efficiency by providing an automated system that ensures consistent quality and reduces labor costs.

The quality of green coffee beans plays a critical role in determining the flavor and commercial value of the final product. Traditionally, inspecting the quality of green coffee beans has relied on manual labor—a time-consuming, labor-intensive process prone to human error. These challenges highlight the urgent need for automated solutions to ensure quick and accurate inspections.

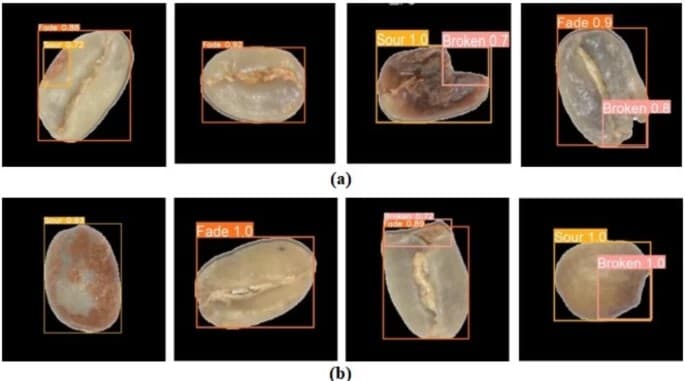

The study demonstrates how AI models can replace manual inspection by offering an automated system capable of detecting and classifying defects, such as black, broken, faded, and sour beans.

The research team comprised Hira Lal Gope, Hidekazu Fukai, Fahim Mahafuz Ruhad, and Shohag Barman. They utilized a dataset of more than 4,500 annotated images to evaluate the performance of six YOLO models, including YOLOv3, YOLOv4, YOLOv5, YOLOv7, YOLOv8, and the custom YOLOv8n model developed specifically for this study.

Green coffee bean samples were collected from farmers in Timor-Leste and photographed using a standardized setup to ensure consistency. Preprocessing techniques, such as enhanced lighting, brightness adjustments, and rotations, were also applied to improve model accuracy.

The custom YOLOv8n model demonstrated outstanding performance, achieving a precision of 0.977, recall of 0.990, and an f1-score of 0.983. Additionally, it recorded a mean Average Precision (mAP) of 0.995, highlighting its ability to detect even subtle defects with exceptional accuracy.

The model’s innovations included:

- Improved Feature Extraction: Adjustments to the model’s internal architecture allowed it to detect detailed features of defects.

- Multi-Scale Detection: Design modifications enabled the model to detect defects of varying sizes and characteristics.

- Customized Bounding Boxes: Tailored to match the unique dimensions of green coffee beans.

- Parameter Optimization: Enhanced learning rates and other settings to improve overall performance.

The study highlighted several practical advantages of using AI in coffee production:

- Enhanced Efficiency: Faster image processing compared to manual inspection, reducing operational costs.

- Consistency: Eliminating human error ensures uniform quality.

- Scalability: The model can adapt to multiple bean types and defect categories across different coffee-producing regions.

The researchers noted that this system could also be applied to other agricultural products, such as detecting crop diseases or assessing the quality of fruits and vegetables.

The study classified defects into four main categories:

- Black Beans: Resulting from unripe or damaged cherries.

- Broken Beans: Damaged during the pulping process.

- Faded Beans: Losing color due to rapid drying or aging.

- Sour Beans: Caused by overripe cherries or improper fermentation.

The model was trained using the Stochastic Gradient Descent (SGD) optimization technique on an NVIDIA Tesla T4 GPU. This approach achieved optimal performance after 150 training epochs.

Despite the success of the custom model, the researchers acknowledged some challenges, including:

- Long Training Times: Addressing this requires additional optimizations.

- Dataset Diversity: Collecting more diverse samples could enhance the model’s generalizability.

- Integration with IoT Technologies: Combining the model with IoT sensors could enable real-time quality monitoring.

Future research aims to address these challenges to develop more comprehensive and scalable solutions.

Developing this AI algorithm marks a significant step toward improving quality standards in the coffee industry. With the unprecedented accuracy provided by the custom YOLOv8n model, producers can achieve excellence in a global market that demands the highest levels of efficiency and consistency.

As this technology continues to evolve, it promises a new era in coffee quality assurance, where producers and consumers alike can look forward to unprecedented levels of efficiency and innovation.